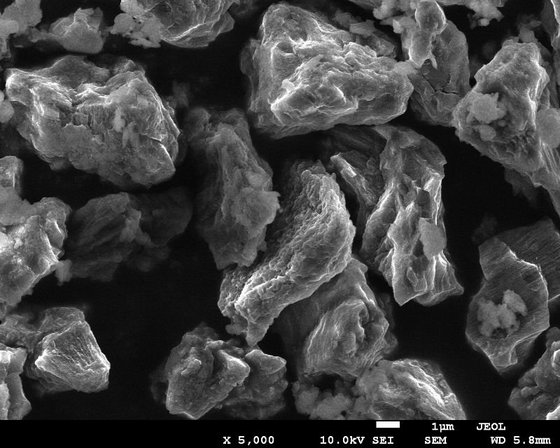

Polycrystalline diamond particles are more tough than monocrystalline diamond microparticles (natural or produced by HPHT) and are widely used in fine polishing. organic light emitting diodes are the superior choice for low cost. The diamond powder with characteristic sizes of particles in the submicron range can be processed from micron-sized polycrystalline diamond particles obtained by shock synthesis. Applied in emission field and CVD film materials.Ħ. layer (Section 5.1.2) until OLEDs with doped amorphous wide gap materials, with and. Used as encapsulation material and magnetic recording system for IT products.ĥ. Coating on metal molds, tools and components, it can improve wear resistance, surface hardness and prolong service life.Ĥ. Used as lubricant or oil additive, it can improve the operation performance of industrial machinery and vehicles, reduce faults and extend service life.Ģ. That’s why it is especially suitable for the high precision machining on super hard material.ġ. These properties allow for higher removal rate and lowest level of scratches. Three elements cutting speed, stability and chip evacuation result in a stable, robust drilling. Therefore, creating efficient drilling operations is important to managing machining costs. Its micro-structured, rough particle surface provides numerous contact points between diamond particles and the work piece. After labor, cutting tools are the largest expense at a machine shop, and drilling is the most common machining operation. Starck is conducting in-depth research into new solar cell thin film material technology in its state-of-the-art thin film material labs and has found that refractory metal-based alloys titanium, molybdenum, niobium and others have unique properties for thin film photovoltaic applications. The structure will always open new sharp edges during the process. Polycrystalline diamond powder is formed by explosion synthesis, leading to a polycrystalline particle structure without cleavage planes.Ĭompared with monocrystalline diamond powder, polycrystalline diamond powder has more cutting edges, resulting in the higher removal rate, with good self-sharpening properties. Crystal shape, strength and accuracy of sizing are the key elements for a quality micron powder. A micron grade designation defines the size range of the abrasive particles. Polycrystalline micro diamond powder(PCDM) 3-6 Used As Lubricant Or Oil Additive Diamond powder or micron powders are well defined ranges of fine particles usually less than 80 microns in diameter.

0 kommentar(er)

0 kommentar(er)